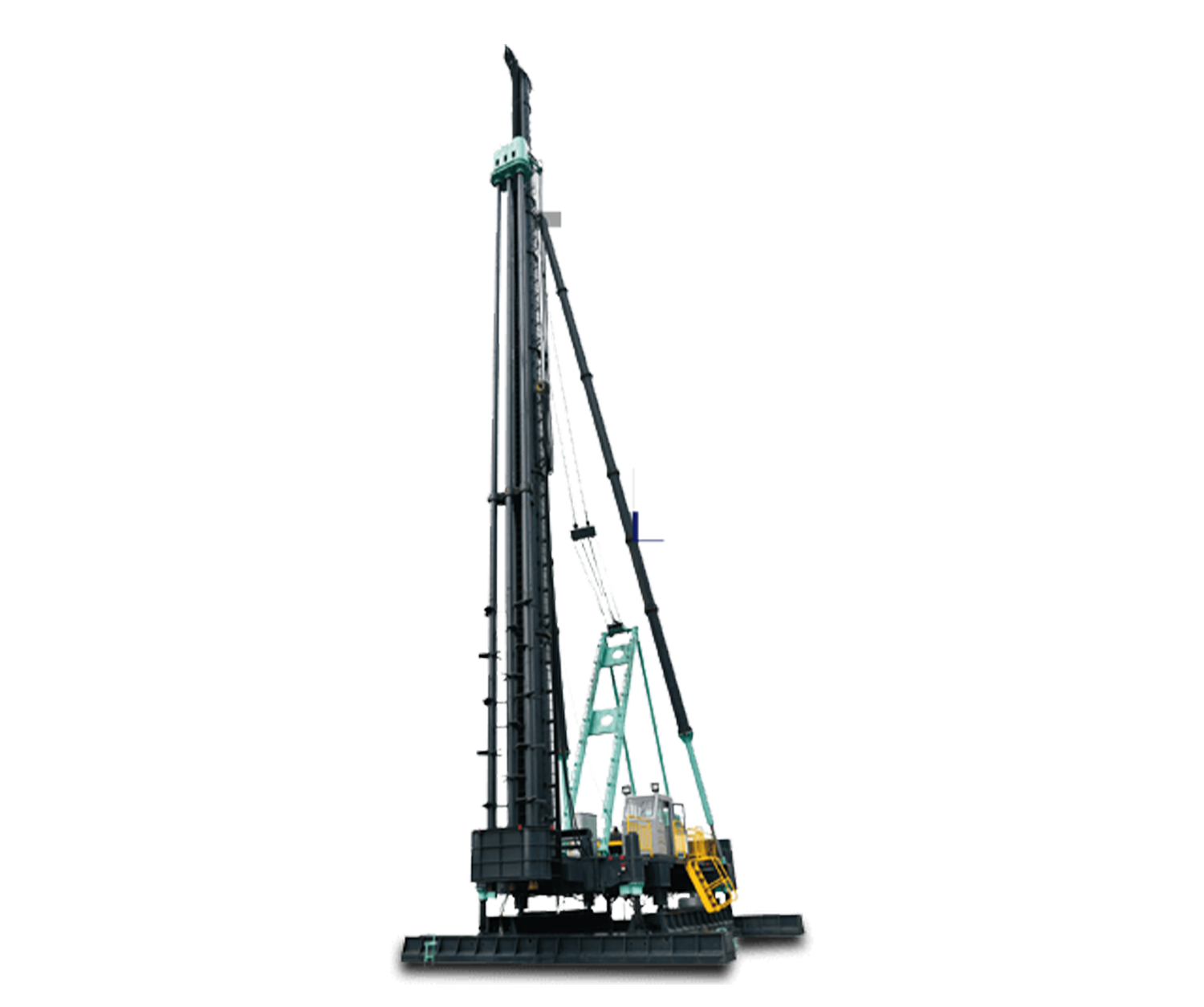

Fully hydraulic walking multi-spindle drilling rig is a mechanical, electrical and hydraulic integrated construction equipment developed to meet the needs of domestic SMW construction method. It is a drilling rig product developed by adopting international advanced technology (SMW construction method) and combining China's national conditions. The equipment can be matched with various specifications of SMW multi-axis drilling tools to realize the construction of deep foundation pits of high-rise buildings, subway stations, anti-seepage, underground retaining walls, waterproof retaining walls, and buried pipeline protection walls. It is also suitable for water conservancy The construction of the anti-seepage wall and soft soil foundation reinforcement of the project is the preferred equipment for the construction of underground pile foundations such as bridges, wharves, and underground continuous walls.

The electrical control of the ZRM220/85-3 full hydraulic walking multi-axis drilling rig adopts a variety of advanced technologies. The power of the drilling rig is driven by electric power. The main and auxiliary winches are driven by hydraulic pressure. It is equipped with a separately controlled air machine. The main motor of the power head adopts a frequency converter. Start/stop/run control, the main oil pump motor adopts online soft starter start/stop/run control; each parameter control of the pile driver adopts programmable logic controller (PLC), and the operation adopts a combination of buttons and switches and touch screen. The safety warning light for drilling rig movement will give out audible and visual alarms when the rig moves piles to warn the surrounding personnel to pay attention to the displacement of the rig; install intelligent lighting control system and air-conditioning to ensure good sight of the rig during night construction and comfortable work in hot weather.

The chassis is stable and reliable, and the column, main platform, and walking mechanism are all designed to meet heavy pile foundation operations;

Equipped with special hoisting hoist, foldable multi-section telescopic mast, can be controlled by the oil cylinder telescopic outrigger, the host platform can be transported as a whole, the equipment disassembly and assembly saves time and effort, and is easy to install and transport;

Large-diameter and high-strength column, hinged three-point support is more stable and safe;

The vertical series structure of imported well-known brand variable hydraulic pump sets is efficient and reliable;

The power head is driven by a planetary reducer and a special motor, which is strong in power and adapts to various complex formations;

The large-capacity main and auxiliary winches are hydraulically controlled to achieve stepless speed change and lock the speed;

The total length of the column is 42 meters, and the drilling depth can reach 35 meters;

Column fine-tuning cylinder stroke 400mm, which increases construction flexibility; The stroke of the jacking cylinder is 900mm, which has better passability;

The horizontal crawler cylinder has a step length of 3.1 meters, which meets the needs of construction method shifting during construction;

All cylinders adopt hydraulic proportional control, which makes the work more stable.

The multi-directional transparent glass operation room is bright and has a wide field of vision;

Simple hydraulic operation mode, operating handle and control panel are all in front of the seat;

Using programmable logic controller (PLC), the buttons and switches are combined with touch screen during operation, all data is clear during operation, saving worry and effort;

Air conditioning can be installed to adjust the operating room temperature, making it more comfortable in winter and summer.

Can be equipped with long spiral to realize CFA construction method;

It can be equipped with down-the-hole hammer to realize rapid rock drilling construction;

It can be equipped with a variety of multi-axis drilling tools to realize SMW construction method;

It can be equipped with hydraulic hammer and diesel hammer to realize precast pile or pipe pile construction;

A special faucet can be installed to perfectly realize high-pressure jet spraying construction.

The power head is driven by a planetary reducer with a special motor, which has strong power and adapts to various complex formations.

1. The multi-directional transparent glass operation room is bright and has a wide field of vision;

2. Using programmable logic controller (PLC), combining buttons and switches and touch screen during operation;

3. Install the drilling rig mobile safety warning light, and sound and light alarm when the drilling rig moves the pile position.

Browse all major components

Browse all major components| Name | ZRM220/85-3 | |

| Total length of column /m | 39-42 | |

| Diameter of column cylinder /mm | Ф920 | |

| Center distance of column guide rail /mm | 600*Ф101.6 | |

| Column angle adjustment range (left and right) /° | ±1.5 | |

| Stroke of diagonal support cylinder /mm | 2800 | |

| Column fine-tuning cylinder stroke /mm | 400 | |

| Maximum column length /m | 42 | |

| Maximum pulling force at maximum column length /kN | 706 | |

| Hydraulic winch (hanging drilling machine) | Single rope pull /kN | 120 |

| Rope speed/m/min | 0-18 | |

| Wire rope diameter /m | Ф21.5 | |

| Rope capacity /m | 550 | |

| Hydraulic winch (lifting, lifting drill pipe) | Single rope pull /kN | 68 |

| Rope speed /m/min | 0-18 | |

| Wire rope diameter /m | Ф20 | |

| Rope capacity /m | 210 | |

| Platform rotation angle (each time) /° | ±10 | |

| Lateral movement of pile frame | Speed /m/min | <1.15 |

| Stride /mm | 3100 | |

| Longitudinal movement of pile frame | Speed /m/min | <1.15 |

| Stride /mm | 800 | |

| Pile frame jacking | Speed /m/min | <0.6 |

| Stride /mm | 450~-450 | |

| Track gauge | When working /mm | 9100 |

| When shifting /mm | 4800 | |

| Wheelbase | When working /mm | 4800 |

| When shifting /mm | 5000 | |

| Horizontal track | Length /mm | 9500 |

| Width /mm | 1209 | |

| Longitudinal shoes | Length /mm | 6900 |

| Width /mm | 1706 | |

| Ground pressure /MPa | ≤0.1 | |

| Motor power /kW | 55 | |

| Hydraulic system pressure /MPa | 20-25 | |

| Main machine weight (excluding drilling tools) /t | 140 | |

| Connection mode of outrigger and platform | Pin rotation, cylinder expansion | |

| Hydraulic system operation mode | Electrical control | |

View parameters

View parameters